The three main types of lathe tooling are: cutting tools, turning tools, and boring tools.

Why Bar Pullers Are Essential in Lathe Tooling

Unattended manufacturing is becoming more common in large and small facilities alike as producers aim to reduce lead times, save costs, and improve ergonomics for employees. In many CNC turning operations, loading and moving bar stock into position is a repetitive task that can be automated. This makes it possible to run the turning center with minimal oversight, which frees operators to manage higher-value or strictly manual tasks.

Bar feeders are a common option for moving bars into position in CNC turning centers; however, they aren’t the only choice. For many applications they aren’t the most efficient or cost-effective either.

Bar pullers are an alternative tool for partially or fully automating CNC turning procedures. As their name implies, bar pullers pull bar stock into a CNC machining center and position it for cutting and shaping. When the current portion is completed or cut from the bar, the puller moves into place, grips the bar, and pulls it forward again, and the process repeats over and over.

Not only do bar pullers support automation, they are also cost-effective and integrate with most CNC lathes. Accudyne designs and develops multiple bar puller options like our EZ-Puller, EZ-Puller Expanded, and BigEZ to meet the needs of different manufacturers.

Learn more about how a CNC lathe bar puller can complement turning operations, how they work, and the unique advantages they offer.

What Is Lathe Tooling?

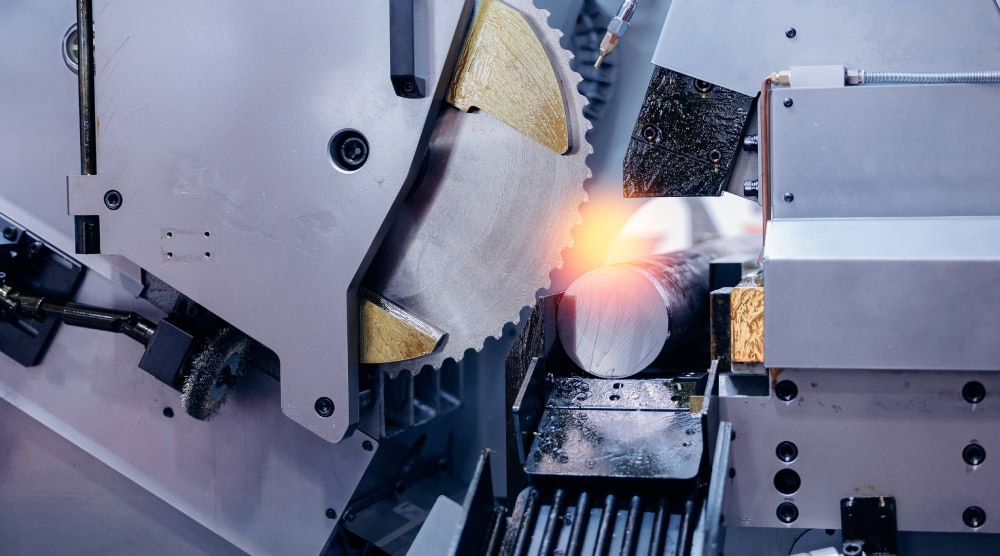

CNC lathes shape metal, wooden, plastic, or composite materials by pressing and moving fixed-position cutting tools onto rotating pieces of stock. This operation, called turning, is used to add threads or knurling, create sections with a smaller diameter, carve out conical or curved profiles, add tapped or bored features, or add symmetrical grooves on the workpiece. Because CNC lathes use precise computer-controlled instructions, they can produce a high volume of consistent, virtually identical parts. Some common applications of CNC lathe turning are:

Types of CNC Lathe Tooling

- Lathe Cutting Tools

Lathe cutting tools are tough, strong tools made of hardened tool steel. They can cut through metal and other materials without becoming dull, and are usually designed for creating specific shapes, features, or profiles. Cutting tools can be made from a variety of materials, depending on what they will be used for and their anticipated service life.

Some common materials include:

- Steel Alloys. These alloys can contain carbon, chromium, and vanadium, and facilitate high-speed turning.

- Tungsten Carbide. This alloy is highly durable and can handle even faster turning speeds than steel tools.

- Diamond. Diamond-tipped or coated cutting tools are very tough but can be cost-prohibitive.

- Cubic Boron Nitride or Ceramic. These materials can operate at very fast cutting speeds and generate minimal heat, which eliminates the need for coolant systems.

- Lathe Turning Tools

- Lathe Boring Tools

Manual vs. Automatic Tooling

Both manual and automatic lathe processes have a role in modern manufacturing. Manual lathes, which the operator holds and applies to the bar, are reserved for simpler handmade products, custom crafting, or products like fine watches. Automated lathes, or CNC lathes, feature machine-controlled cutting tools that deliver high-precision results in high-volume applications across multiple industries.

The Benefits of Using Bar Pullers in CNC Machining

CNC bar pullers offer unique advantages over manual operations and CNC bar feeding tools. Consider these benefits of streamlined processes with Accudyne bar pullers:

Cost Savings

Bar pullers cost in the hundreds of dollars, making them a more affordable option than bar feeders. Bar pullers also take up far less floor space, and do not take away from space for neighboring machinery or the flow of foot traffic. They are a great automation solution for small work environments or larger settings too.

As automation tools, they offer benefits for workflow, ergonomics, and precision capabilities as well. Operators can prioritize more complex or profitable tasks, oversee additional centers, or focus on intricate manual work instead of manually feeding bars into the machining center This can reduce costs associated with labor, fatigue-related errors, or repetitive movement injuries.

Simple Setup and Operation

Accudyne develops user-friendly bar pullers that are highly reliable and effective. Our EZ Bar Puller has a one-time easy setup and doesn’t require ongoing mechanical adjustments to do work. The CNC program tells the bar puller how to adjust the X-axis endpoints for bar stock of different diameters without human intervention. By limiting manual intervention strictly to advancing the bar, you can more efficiently manage work at a fixed location or even across different jobs and workstations.

Versatility and Efficiency

Bar pullers can accommodate changing bar sizes with less material waste and far fewer delays than manual operations. Instead of gripping fingers that can break and require manual adjustment, our EZ Puller products feature versatile gripping mechanisms that can handle bars in these ranges without spindle orientation:

- Round: 0.9 in. – 1.750 in.

- Hex: 0.125 in. – 1.375 in.

- Square: 0.125 in. – 1.000 in.

Safety

Bar pullers significantly reduce manual tasks. This keeps workers safer by reducing their interactions with potentially dangerous machines, moving equipment, or sharp blades and material edges. Stress from repetitive motions is also reduced, for more ergonomic work. All of this contributes to cost savings over time.

Contact Accudyne Products for Bar Pullers for Use with Lathe Tooling

Accudyne Products designs and manufactures high-performance bar pullers that offer automation without the costs or space demands associated with bar feeders. We work hard to develop cutting-edge solutions and tools that optimize your CNC turning and machining processes.

With our EZ Bar Puller equipment, you can automate more of your operations, protect your staff, and complete small and large orders faster. Our bar pullers are long-lasting tools that are easy to use and maintain. We also provide grippers, springs, replacement parts, and more.

Contact us today to learn more, or explore our online store to see the options available.