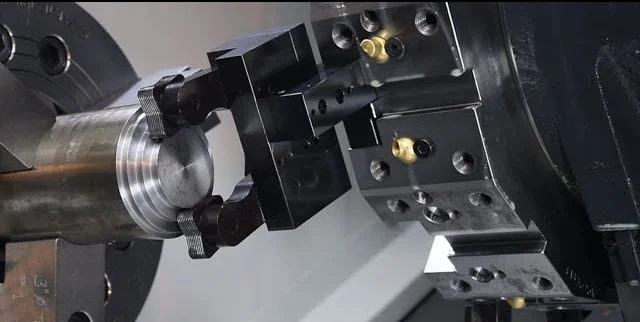

At Accudyne Products, we make bar pulling effortless and reliable, supporting machinists in achieving seamless CNC lathe automation and maximum productivity. As the manufacturers of the EZ-Puller, our CNC lathe bar puller systems eliminate the hassle of complex setups, providing a simple, cost-effective solution for a range of bar diameters. From the EZ-Puller Original to the BigEZ for larger capacities, our products are engineered for high-speed operation, incredible repeatability, and rugged durability.

Why Choose Accudyne’s Bar Puller Solutions

Our lathe bar puller systems stand out for their robust design and ease of use, tailored to meet the rigorous standards of modern manufacturing. Designed to handle round, hex, and square stock without requiring spindle orientation, Accudyne’s bar puller for CNC lathe operations supports both short-run and high-volume production with quick setup and precise adjustment.

With the flexibility to work across varied bar sizes, our tools offer:

- Quick and Easy Setup: Adjust the bar size once, then let it run without further modification, saving time and minimizing downtime.

- High-Speed Production: Increase parts produced per hour, reduce labor costs, and boost productivity with reliable bar puller CNC lathe systems designed for speed.

- Exceptional Repeatability: Maintain consistent results, reduce waste, and improve resource efficiency through highly repeatable operations.

- Built to Last: Manufactured from high-quality materials, our lathe bar puller systems offer extended tool life, backed by a two-year limited warranty and a 60-day money-back guarantee for your peace of mind.

Why Choose Accudyne’s Bar Puller Solutions

Our lathe bar puller systems stand out for their robust design and ease of use, tailored to meet the rigorous standards of modern manufacturing. Designed to handle round, hex, and square stock without requiring spindle orientation, Accudyne’s bar puller for CNC lathe operations supports both short-run and high-volume production with quick setup and precise adjustment.

With the flexibility to work across varied bar sizes, our tools offer:

- Quick and Easy Setup: Adjust the bar size once, then let it run without further modification, saving time and minimizing downtime.

- High-Speed Production: Increase parts produced per hour, reduce labor costs, and boost productivity with reliable bar puller CNC lathe systems designed for speed.

- Exceptional Repeatability: Maintain consistent results, reduce waste, and improve resource efficiency through highly repeatable operations.

- Built to Last: Manufactured from high-quality materials, our lathe bar puller systems offer extended tool life, backed by a two-year limited warranty and a 60-day money-back guarantee for your peace of mind.

Explore Our Range of EZ-Puller Models

- EZ-Puller Original: Handles round stock up to 1.750”, hex up to 1.375”, and square stock up to 1.000”. Ideal for standard applications with multiple mounting options.

- EZ-Puller Expanded Capacity: Extends the range up to 2.000” round stock for added versatility in machining applications.

- BigEZ: Designed for heavy-duty jobs, accommodating round stock between 1.750” and 3.250”.

Each model comes with a variety of mounting bar options to fit most CNC lathes, including square, round, and low-profile configurations.

More Information About Urethane Springs

Hardness 95A

The standard springs (95A) are for all materials within the range of the tool. These standard springs are built for high speed and repeatability (maximum rapids 300 IPM X and Z). However, they will leave a mark .001-.005” on the outside of the material. Not recommended for thin wall tube. (Related item for hardness comparison – Skateboard wheel).

Hardness 80A

Medium duty springs (80A) will leave less of a mark on the rod .0005”- .003” depending on size and base material. We recommend having very good support inside the spindle and good clearance in the chuck/collet. Thinner wall tube is okay. (Related item for hardness comparison – Shoe Heel).

Hardness 70A

Light duty springs (70A) will not leave a mark on most materials. These are for jobs that require very little or no marking on the OD of the part (steel and aluminum). We recommend pulling slower – 100 inches per minute maximum. Also, perfect support inside the spindle with excellent clearance. (Related item for hardness comparison -Car Tire).

Unmatched Benefits of CNC Lathe Bar Pullers

The EZ-Puller series is trusted for high-precision performance in manufacturing operations, allowing machinists to focus on productivity without the need for constant adjustment. Whether for high-speed, unattended operation or reliable performance across diverse bar types and sizes, our CNC lathe bar puller products are designed to:

- Optimize Workflow: Automate processes and reduce manual intervention, allowing operators to manage multiple machines at once.

- Lower Production Costs: Increase parts per hour while decreasing labor and setup costs, offering a substantial ROI over traditional bar feeders.

- Reduce Waste: Efficiently utilize bar stock, minimizing material waste and improving sustainability.

Contact Our Team Today!

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Drive Your CNC Lathe Efficiency with Accudyne’s EZ-Puller

Discover how Accudyne’s bar puller for CNC lathe systems can transform your CNC lathe operations into a streamlined, cost-effective production powerhouse. Contact our team today to find the ideal model for your application and get a personalized quote. Let’s elevate your manufacturing process with precision tools built to last.