Store

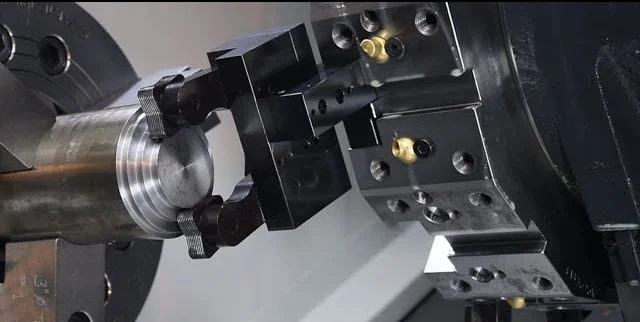

Bar Pullers

We Make Bar Pulling Easy AND Productive:

- Quick and Easy Set-up: Save countless hours of intricate and frustrating adjustments. Adjust once to the bar size and let it run.

- High Speed Operation: Increase parts produced per hour and lower production costs.

- Incredible Repeatability: Minimize waste of bar stock raw material.

- Robust design for Long Tool Life: Avoid downtime or frequent replacement costs – comes with a 2-year warranty.

Store

Replacement Parts

We Make Replacing Your Bar Puller Parts Easy AND Productive:

- Quick and Easy Set-up: Save countless hours of intricate and frustrating adjustments. Adjust once to the bar size and let it run.

- High Speed Operation: Increase parts produced per hour and lower production costs.

- Incredible Repeatability: Minimize waste of bar stock raw material.

- Robust design for Long Tool Life: Avoid downtime or frequent replacement costs – comes with a 2-year warranty.

More Information About Urethane Springs

Hardness 95A

The standard springs (95A) are for all materials within the range of the tool. These standard springs are built for high speed and repeatability (maximum rapids 300 IPM X and Z). However, they will leave a mark .001-.005” on the outside of the material. Not recommended for thin wall tube. (Related item for hardness comparison – Skateboard wheel).

Hardness 80A

Medium duty springs (80A) will leave less of a mark on the rod .0005”- .003” depending on size and base material. We recommend having very good support inside the spindle and good clearance in the chuck/collet. Thinner wall tube is okay. (Related item for hardness comparison – Shoe Heel).

Hardness 70A

Light duty springs (70A) will not leave a mark on most materials. These are for jobs that require very little or no marking on the OD of the part (steel and aluminum). We recommend pulling slower – 100 inches per minute maximum. Also, perfect support inside the spindle with excellent clearance. (Related item for hardness comparison -Car Tire).

Contact Our Team Today!

Lorem ipsum dolor sit amet, consectetur adipiscing elit